Designing and Installing Compressed Air Piping

Ayser have expertise in design and installation of different types compressed air piping for variety of industries such as

TYPES OF PIPING OFFERED FOR COMPRESSED AIR

We design and install Metal and Non-Metal piping for compressed air.

Non-Metal Pipe — commonly called “plastic” pipe, has been offered for many years as compressed air piping because:

- It is lighter than most metal and easier to handle.

- It can be installed with no special tools (such as welders, threaders, etc).

- It is generally non-corrosive.

- Installation with the appropriate gluing material is fast.

- The labor (which can also be unskilled) is less costly than most metals (copper, stainless, black iron), and the total job may often be less expensively installed.

Metal pipe used for a compressed air system can be black iron, stainless steel, copper, aluminum, etc. with proper thermal/pressure characteristics.

Black Iron or Steel Pipe — in compressed air systems will corrode when exposed to condensate (H2O) and thus become a major source of contamination to the whole system. This pipe usually has threaded connectiions when it is 3″ diameter and smaller. It is typically welded if the diameter is larger than 3″. Compared to copper and aluminum, it is much heavier and harder to work with, but less expensive. The internal corrosion issue is much more significant with oil- free air than with lubricated compressors.

Stainless Steel — is often a good selection particularly when exposed to oil-free wet air and its extremely high acid level condensate (before the dryers). Stainless steel is often lighter for the same pressure temperature rating and installs well when welded. Threaded stainless steel often tends to leak. Ring seals such as those used in Victaulic connections will work well here. As piping material however, the potential lower installation cost and faster welding (use of Victaulic fittings) may well make it the most overall economical.

Copper Pipe — is a common selection for sensitive air systems. When selected and connected correctly it is very rugged. The working pressure of copper piping is 250 psi for Type “M” hard, Type “L” hard and Type “K” soft and 400 psi for Type “K” hard. Further, since 50/50 solder melts at 421°F, it will be more resistant to high temperatures. Even if it does fail, it will do so in a predictable manner. The pipe ends will separate. The working temperature limit of copper piping is about 400°F. (Data from Piping Handbook, 6th edition).

Aluminum compressed air pipe as applied today has become very popular. This has been developed not only to provide smooth (low pressure loss due to friction) inner surface and eliminate “self contamination,” but also to offer enhanced flexibility to meet the ever-changing compressed air distribution needs. This is particularly desirable in the automotive support industry with changing assembly and sub-assembly areas. Note: most aluminum pipe manufacturers rate their material at +4°F to 140°F or 176°F. The piping material usually has a melting point of over 1,100°F.

Linear pipe system

This is a great alternative when a closed-loop configuration is not possible. In a perfect world, the compressor station would be ideally located in the centre of the linear network. This allows air to flow in both directions from the compressor to the furthest ‘drop’, or point of use. Another option is to install more than one compressor, however they may struggle to operate in harmony, as they battle for the lead position in the system pressure pecking order.

Closed loop systems

Often referred to as a ring main, they are considered to be the most efficient configuration, but require more pipe, fittings, and labour to create and install them. The benefits of a closed loop system far outweigh the additional expense, as the loop/ring promotes equal, and uniformed system pressure from generation to point of use – with a balanced and equal flow of PSI pressure and CFM volume for all users. No one is starved of pressure.

CFM pipe work volume

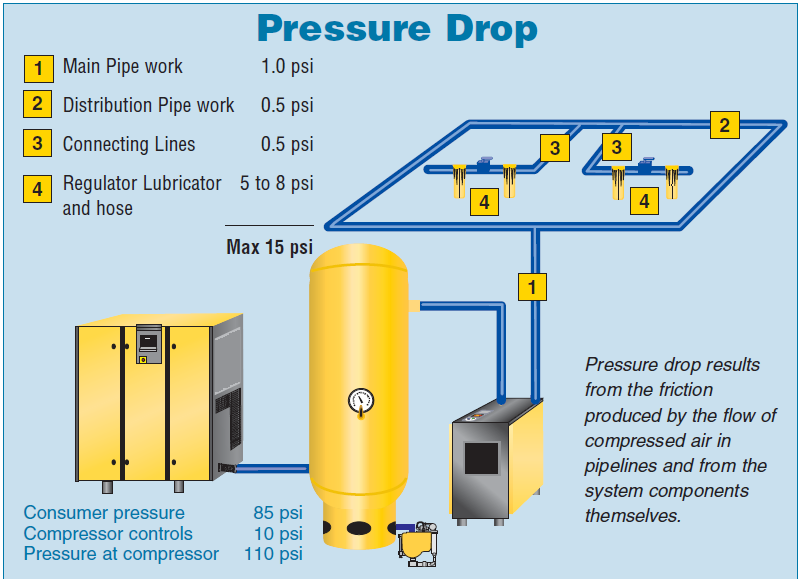

Selecting the correct size of compressed air pipe work is vitally important in providing adequate CFM volume flow, and stable system pressure to all of your points of use. The pipe diameters you install will dramatically impact system pressure drop, and available volume at point of use. Poor choices in pipe materials, diameter, and layout cause flow restrictions, which often result in significant pressure drop. Pressure drop is a leading cause of increased energy consumption, disgruntled end users, poor performance of cylinders, valves, air driven tools and equipment.

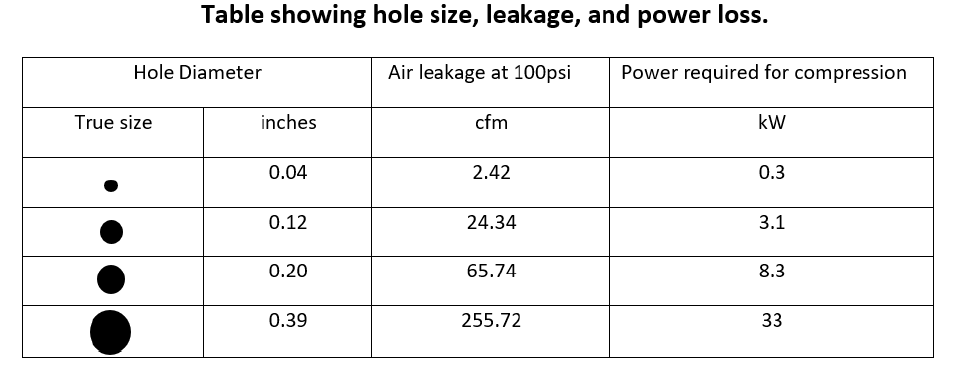

An estimated 15% of the total compressed air generated in a typical manufacturing or production facility is lost to leaks. That’s a staggering waste of money and Hydro energy. To provide context, a 100hp (75kW) rotary screw air compressor operating 2 shifts, 5 and a half days a week, with Hydro costs of INR 6.4 per kW/hr. would rack up a Hydro bill of approximately 15 lac per year.

In this example, compressed air leaks are responsible for INR 15 lac of this Hydro bill.

Needless to say, leak detection is a low hanging fruit to pick, and essential to the reduction of the cost of compressing air. The ROI from identifying compressed air system leaks, and following up with repairing them, is rewarding, and rapid.