Klüber Air Compressor Oils

Your benefits

- Reduced downtime

- Reduced costs for replacement parts, oil filters and oil separators

- Longer oil life

- Prevents deposit on compressor parts

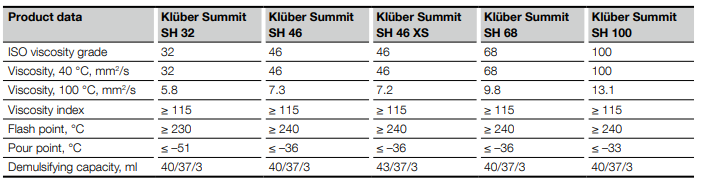

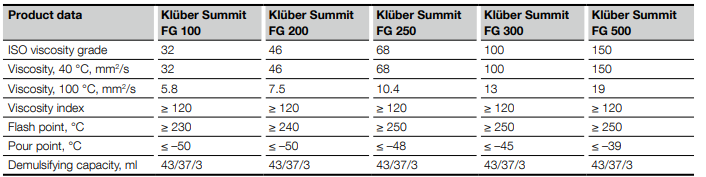

- Low pour point

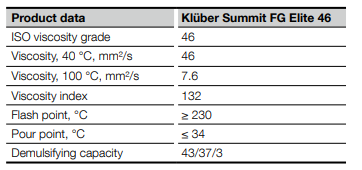

- Excellent water demulsibility

- Klüber Summit compressor oils have also proven effective for the lubrication of gears in oil-free rotary screw compressors

- Extended drain intervals

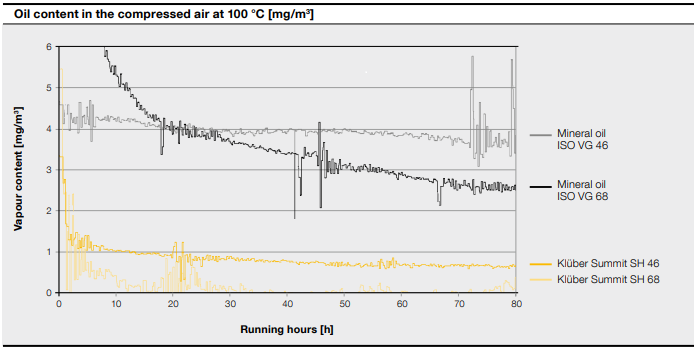

- Less evaporation

- Improved oxidation protection

- Reduced make-up consumption

- For oil change intervals of up to 12,000 hours depending on the operating conditions and type of oil

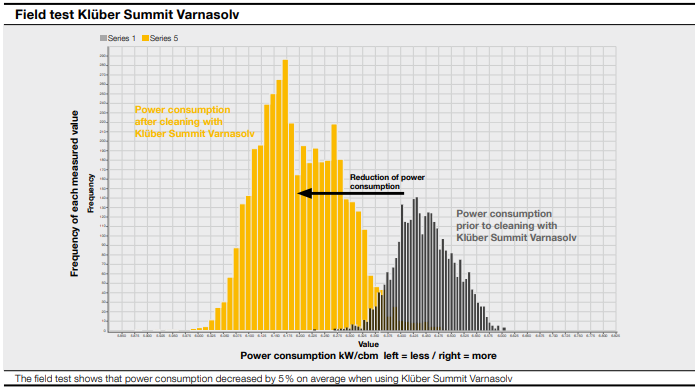

- Reduced power consumption

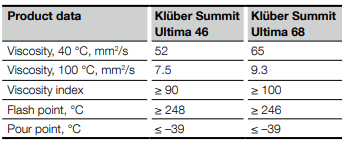

- Improved thermal efficiency

- Improved mechanical efficiency

- Reduced friction

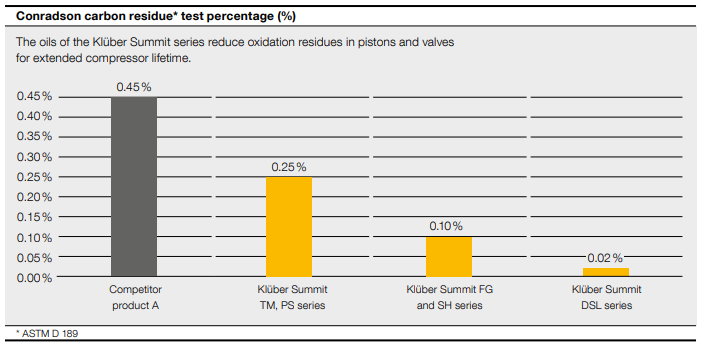

- Virtually a carbon-free system

- Superior oxidation resistance

- Higher auto-ignition temperature

- Lower operating temperature

- Reduced residue formation

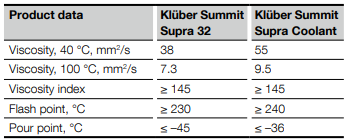

Longer valve lifetime - Klüber Summit Supra 32 and Klüber Summit PS 100

compressor oils have also proven effective for the lubrication of gears in oil-free rotary screw compressors