100% OIL FREE SCROLL AIR COMPRESSORS

Industrial Applications of oil free Scroll Compressors

Industrial Applications of oil free Scroll Compressors

KEY FEATURES AND BENEFITS OF THE ANEST IWATA OIL FREE SCROLL COMPRESSORS

The Most Advanced Technologies for High-Quality air

Class Zero Certification TÜV (independent third party test house) has just certified that the air quality from our oil free scroll compressors is in conformity with “Class 0 (ISO8573-1:2010[-:-:0])“.

What is Class Zero?

SO8573-1(JIS B8392-1) defines quality classes for compressed air. Class Zero indicates wall flow oil, oil mist and oil vapor are completely absent. As oil vapor in particular cannot be absorbed by conventional air filters, it is important factories that require clean air use Class Zero compressors

Low Contamination Risk Clean Air from oil-lubricated compressors contains oil and can contaminate the piping. This does not happen with an Oil free Scroll Compressor which produces high-quality oil free air.

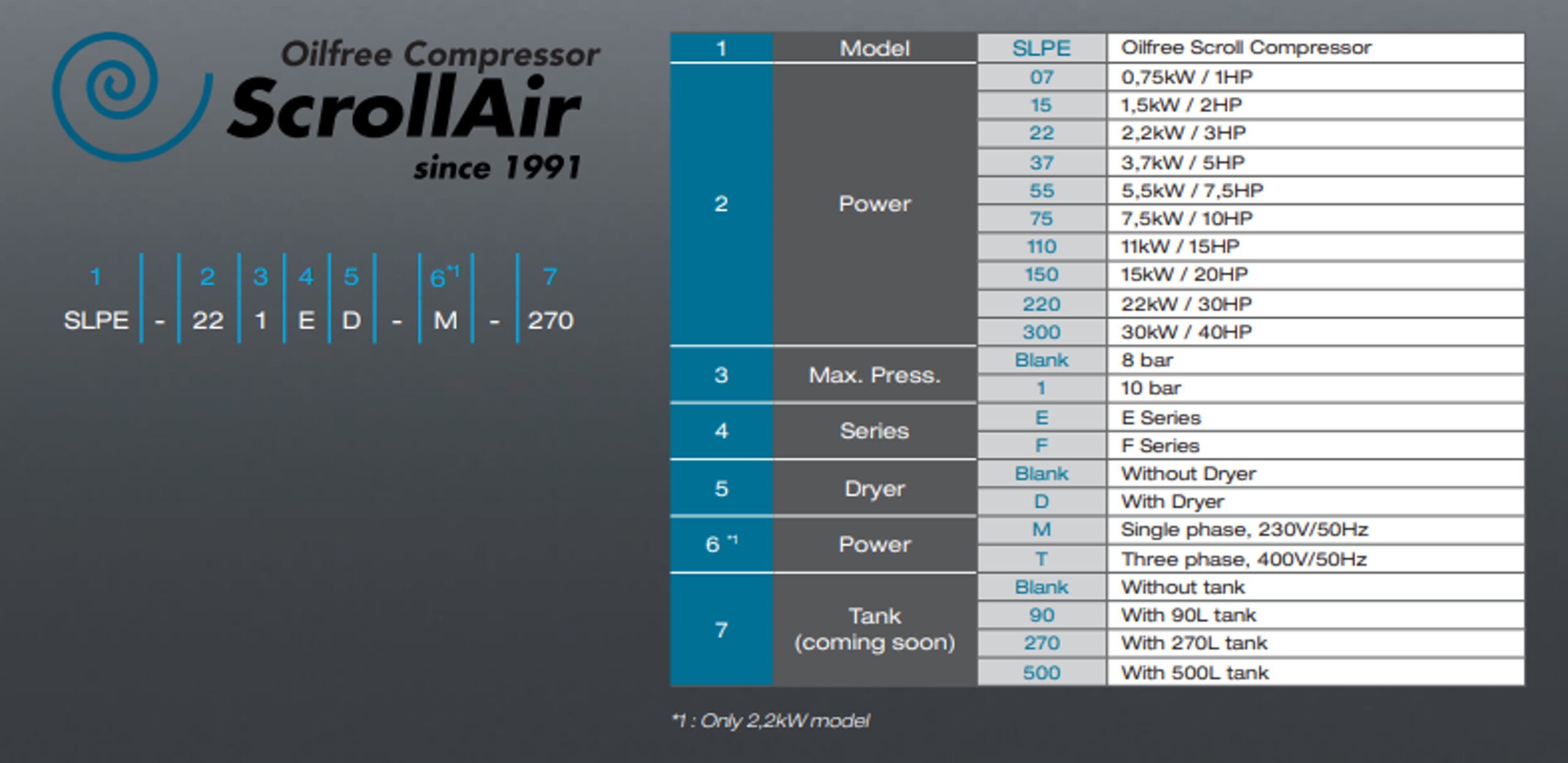

SIMPLEX OIL- FREE SCROLL COMPRESSORS.

Single & Two stage oil free reciprocating compressors deliver clean, dry air with maximum reliability, energy efficiency and ease of maintenance to meet the exacting demands of oil free air across various industries.

Major Applications

- All ISO 14001 industries for 100% oil free air

- Hospitals Nursing homes and Dental clinics

- Hardware manufacturing

- Nitrogen generators

- Electronic industries

- CNC machines and instruments

- Petroleum and gas

- Cooler sorting

- Laboratories

MULTIPLEX OIL- FREE SCROLL COMPRESSORS.

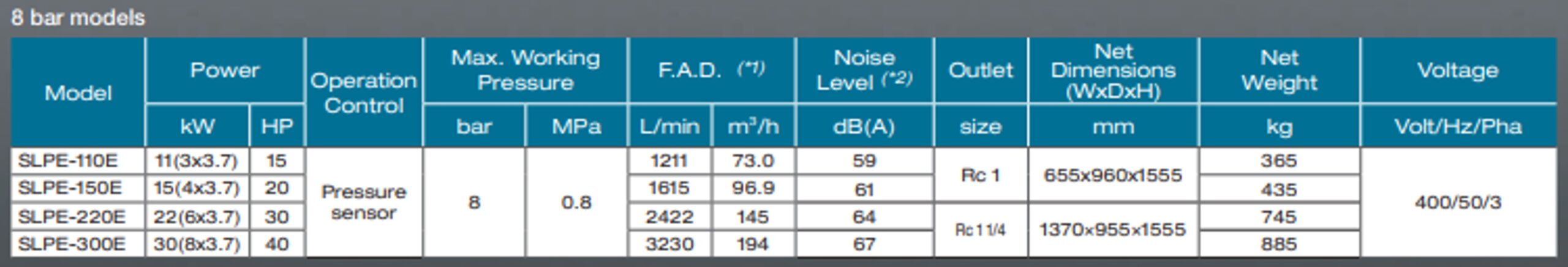

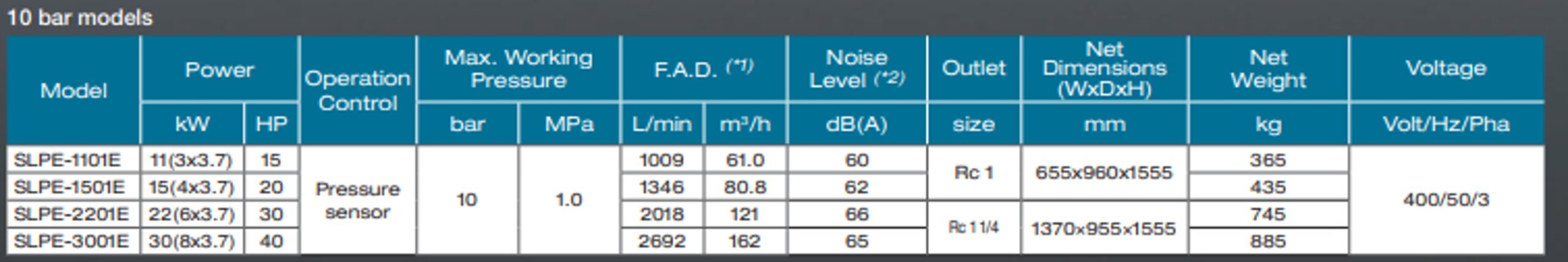

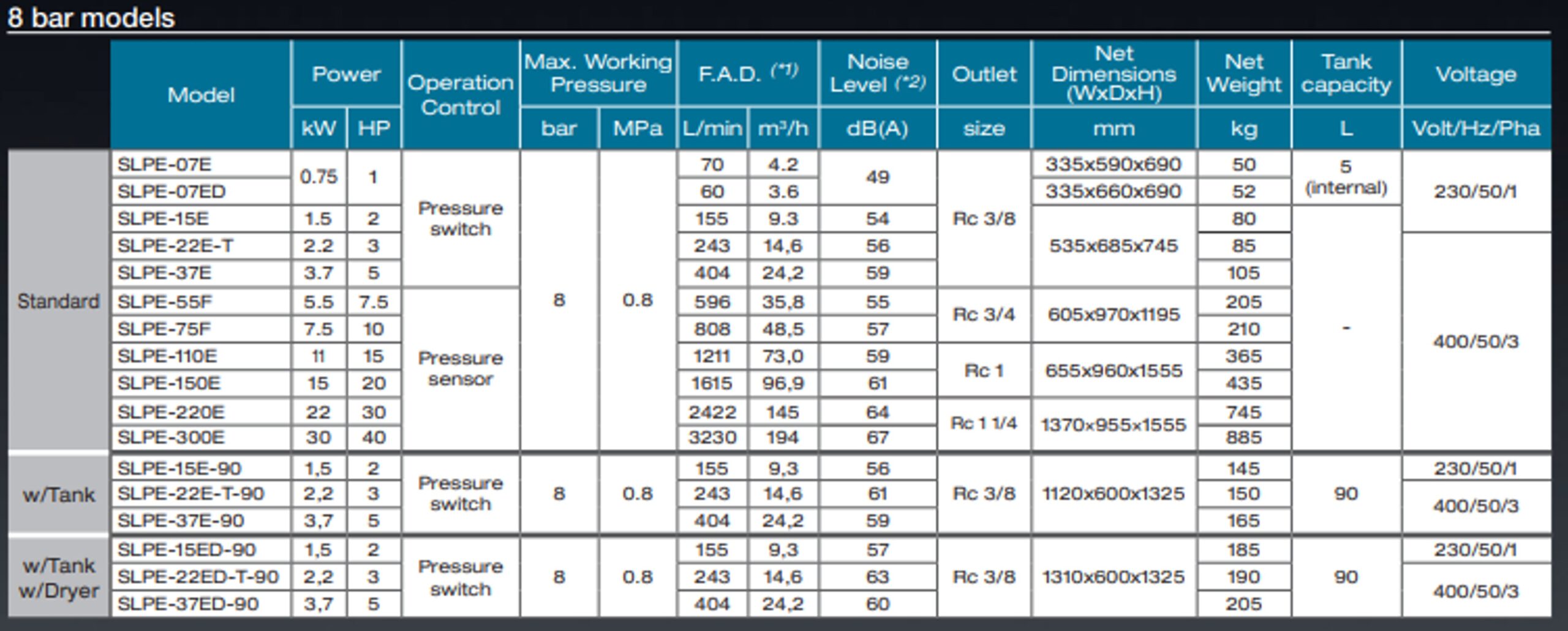

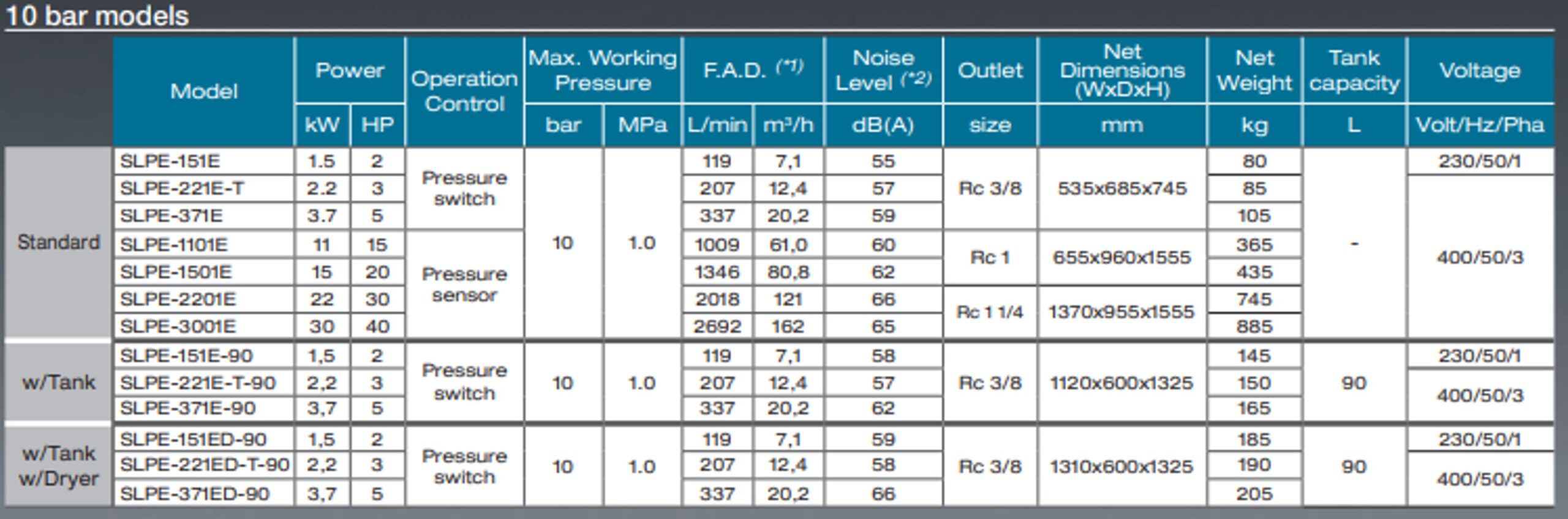

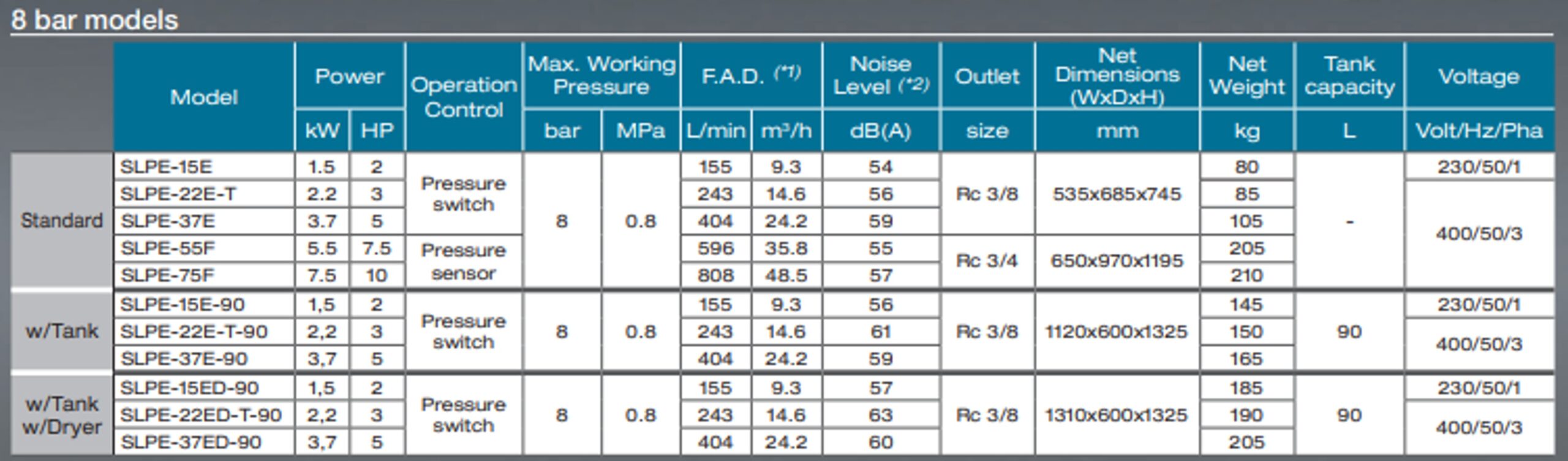

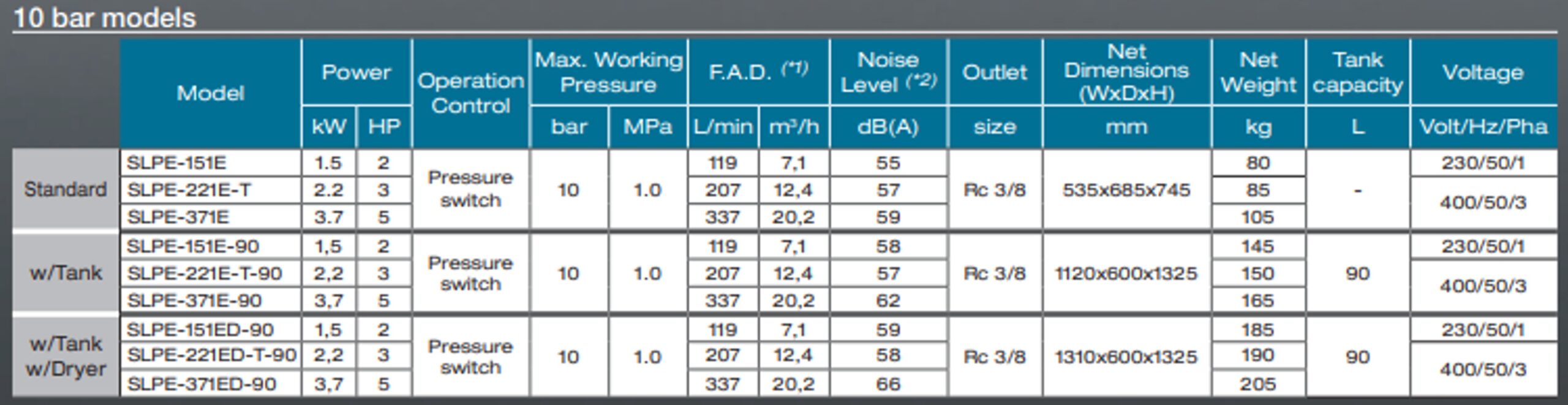

- F.A.D. is measured at max working pressure.

- Noise level measured at a distance of 1M according to ISO11201; tolerance±3dB

- 3-1 Except intake filter

- 3-2 5000 hrs. for 10 bar models

- It is recommended to install air filters and an external receiver tank after the compressor.

- Even with Class zero compressors, oil may be found in the piping.

This may be caused by the presence of oil in the piping before installation of the compressor or by accident during the production process