- Cast iron design for durability and long life

- Special honing of cylinders resulting in low friction between cylinders and piston rings

- Compact and easy to install – No foundation required

- Low noise – Ideal for hospital applications

- Higher efficiency resulting in power savings

- Low oil carry over and low maintenance cost

RECPROCATING VACUUM PUMPS

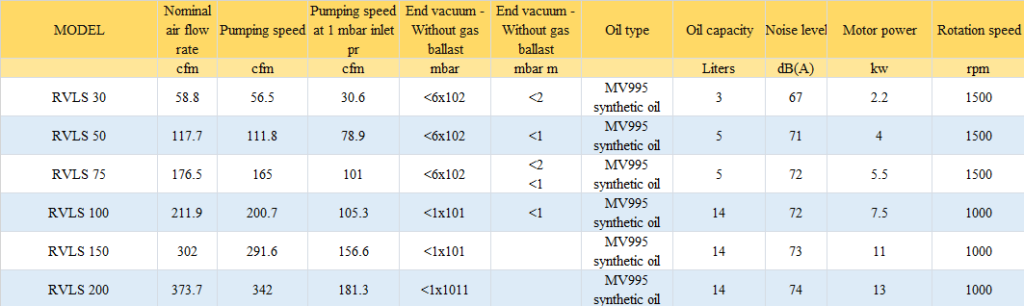

ROTARY VANE VACUUM PUMPS

What is a Rotary Vane Vacuum Pump? What is the Purpose of Rotary Vane?

A Rotary Vane Vacuum Pump is a versatile and essential tool used to create a vacuum by removing gas molecules from a sealed chamber. It operates based on a rotary vane mechanism, which consists of a set of vanes that rotate within the pump’s chamber. As the vanes rotate, they compress gas and push it towards the exhaust, effectively creating a partial vacuum

- Robust No Wear

- Reliable

- Cost Effective

- Energy Efficient

- Single stage vacuum pump

- Continuous operation fromatmospheric pressure to end vacuum: 5.10⁻¹ mbar

- Integrated oil mist filter on the exhaust

- High pumping speed evenat a lower pressure

Anest Iwata dry scroll vacuum pumps provide oil-free, air cooled vacuum pumping to the low millitorr range. The Anest Awata oil-free, scroll vacuum pumps are compact and emit less noise and vibration than other comparable dry pumps. Sizing starts at the ISP 50 (50 cu.meter/hr pump speed) and ranges through the ISP 90, ISP 250, ISP 500 to the ISP 1000. Anest Iwata was the first to develop oil-free air cooled scroll pump technology and have been highly valued by customers who need clean, high quality pumping.

ISP Scroll Pumps maintain low power consumption from atmosphere to maximum vacuum.

Anest Iwata Dry Scroll Pumps have been the choice for backing high vacuum pumps at locations all over the world. These robust vacuum pumps can be found at all National Laboratories in the USA and at every major university department such as physics, chemistry, material science and engineering research laboratories.

Pump Speed (50/60 Hz)- 1000/1200 l/m ( (35.3/42.4)cfm) Ultimate Pressure 0.0075 torr NW40 Flang

Pump Speed (50/60 Hz)- 90/108 l/m (3.2/3.8cfm) Ultimate Pressure 0.037 torr NW25 Flange

Pump Speed (50/60 Hz)- 250/300 l/m (8.8/10.6cfm) Ultimate Pressure 0.037 torr NW25 Flange

Pump Speed (50/60 Hz)- 500/600 l/m (17.7/21.2cfm) Ultimate Pressure 0.0075 torr NW40 Flange

Pump Speed (50/60 Hz) - 50/60 l/m (1.8/2.1cfm) Ultimate Pressure 0.11 torr NW25 Flange

DRY SCROLL VACUUM PUMPS

VACUUM PUMPS

INDUSTRIAL APPLICATIONS OF VACUUM PUMPS

Where are Vacuum Pumps Required?

HEALTHCARE

- Surgery

- Obstetrics

- Anesthesia, resuscitation

FOOD AND BEVERAGE INDUSTRY

- Cutter, filling or tumbler machine

- Freeze drying

- Lyophilization

- Poultry processing

- Vacuum packaging or mixing

SOLAR AND ENERGY INDUSTRY

- Coating

- Handling

- Lamination

- Oil Degassing

- Power engineering

GLASS INDUSTRY

- Coating

- Formin

GENERAL PURPOSE

- Central vacuum supply

- Leak detection

- Packaging

- Picking and handling

- Pneumatic conveying

CHEMICAL AND PHARMACEUTICAL INDUSTRIES

- Degassing

- Distillation

- Drying and Freeze drying

- Packaging

PLASTIC AND COMPOSITE INDUSTRY

- Degassing

- Pneumatic conveying

- Resign transfer

- Vacuum bagging

INDUSTRIAL APPLICATIONS OF VACUUM PUMPS

Where are Vacuum Pumps Required?

HEALTHCARE

- Surgery

- Obstetrics

- Anesthesia, resuscitation

FOOD AND BEVERAGE INDUSTRY

- Cutter, filling or tumbler machine

- Freeze drying

- Lyophilization

- Poultry processing

- Vacuum packaging or mixing

SOLAR AND ENERGY INDUSTRY

- Coating

- Handling

- Lamination

- Oil Degassing

- Power engineering

GLASS INDUSTRY

- Coating

- Formin

GENERAL PURPOSE

- Central vacuum supply

- Leak detection

- Packaging

- Picking and handling

- Pneumatic conveying

CHEMICAL AND PHARMACEUTICAL INDUSTRIES

- Degassing

- Distillation

- Drying and Freeze drying

- Packaging

PLASTIC AND COMPOSITE INDUSTRY

- Degassing

- Pneumatic conveying

- Resign transfer

- Vacuum bagging